- +86 152 1709 1354

- [email protected]

- Dongguan,China

- Blog

What materials can be precision ground?

Not all materials can be processed with precision mechanical parts. Some materials are too hard and exceed the hardness of the machining parts, which may break the parts, so these materials are not suitable for machining precision mechanical parts unless they are Machine parts made of special materials, or laser cut.

The materials for machining precision mechanical parts are divided into two categories, metallic materials and non-metallic materials. For metallic materials, the hardness is greater than stainless steel, followed by cast iron, followed by copper, and then aluminum. The machining of ceramics and plastics is attributed to the machining of non-metallic materials.

The machining of precision mechanical parts mainly requires the hardness of the material. For some occasions, the higher the hardness of the material, the better. It is only limited to the hardness requirements of the machining machine. The processed material cannot be too hard. It is impossible to assume that it is harder than the machine. machining. The materials are moderately soft and hard, at least one level lower than the hardness of the machine parts, and it also depends on the purpose of the processed devices, and the reasonable selection of materials for the machine parts.

There are still some requirements for materials in the machining of precision mechanical parts. Not all materials are suitable for machining. For example, materials that are too soft or too hard are not necessary for the former, while the latter cannot be processed. Therefore, you must pay attention to the density of the material before machining.

What density parts can be precision ground?

Assuming that the density is too large, it is equivalent to a high hardness, and if the hardness crosses the hardness of the machine (lathe turning tool), it cannot be processed, and it will not only damage the parts, but also pose a danger, such as the turning tool flying out and hurt People wait. Therefore, in general, regarding mechanical machining, the material material should be lower than the hardness of the machine knife, so that it can be processed.

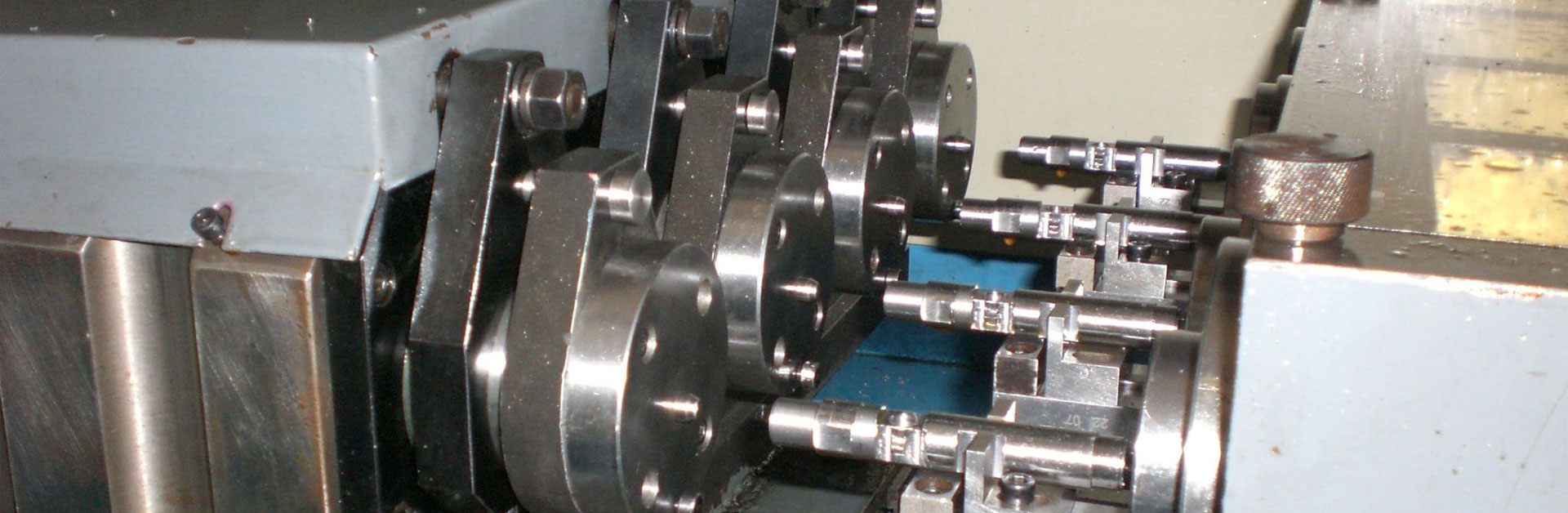

The process of precision grinding

In the machining of precision mechanical parts, we must first formulate the machining technology of mechanical parts to ensure that every link is normal. In the machining of precision mechanical parts, milling is used to produce and process a variety of metal materials and metal materials, and can carry out production machining on plan drawings, inner and outer cylindrical surfaces and cone surfaces.

The whole process of milling can be done by mineral acid abrasive particles according to the research tool to carry out micro-analysis drilling of steel parts, including the comprehensive effects of complicated physics and organic chemistry. Because the raw material of the research tool is softer than the raw material of the steel parts being researched, the abrasive particles in the abrasive are placed in the surface of the research tool or fluctuate to form a multi-blade matrix. When the research tool and the steel parts are used for grinding and fitness exercises, they must work Under pressure, micro-analysis drilling on the surface of steel parts.

When chromium oxide, polyether or other abrasives are used, a very thin layer of air oxide will be produced on the surface of the steel parts. This layer of air oxide is very easy to be removed, and the air oxide film is constantly in the process of grinding It is produced quickly and continuously removed by plants, which accelerates the whole grinding process and reduces the roughness.

Passivated abrasive particles are extruded on the surface of the steel parts, causing deformation of the raw materials being processed. The peaks and valleys of the steel surface tend to be flattened during plastic deformation or cold work hardening during continuous deformation, and the micro-cracks produce tiny Cutting.

12 small experiences in CNC machining

At present, many domestic CNC machine tool operators are classified as follows: some operators are very familiar with mechanical processing, ...

Read More →

Selection of parting surface of die casting mold

In order to remove the blank from the die casting mold, the mold needs to be properly divided into several ...

Read More →

What is sheet metal?

Sheet metal is a metal product processing technology, and there is no complete definition of sheet metal so far.According to ...

Read More →

Where is the road to CNC machining development?

A few days ago, PTJ Engineering issued a document saying that it “processed CNC low-cost orders.” This will hurt yourself ...

Read More →

Skillful use of 4 types of CNC Machining technology

First, the undercut knife method Outer convex processingAs shown in FIG. 1, when the outer opening is projected outward, the ...

Read More →

Stainless steel UG crankshaft CNC machining technology

The crankshaft is the center of the internal combustion engine and the core of the engine. If the function cannot ...

Read More →