- +86 152 1709 1354

- [email protected]

- Dongguan,China

- Blog

What is Chip Breaking?

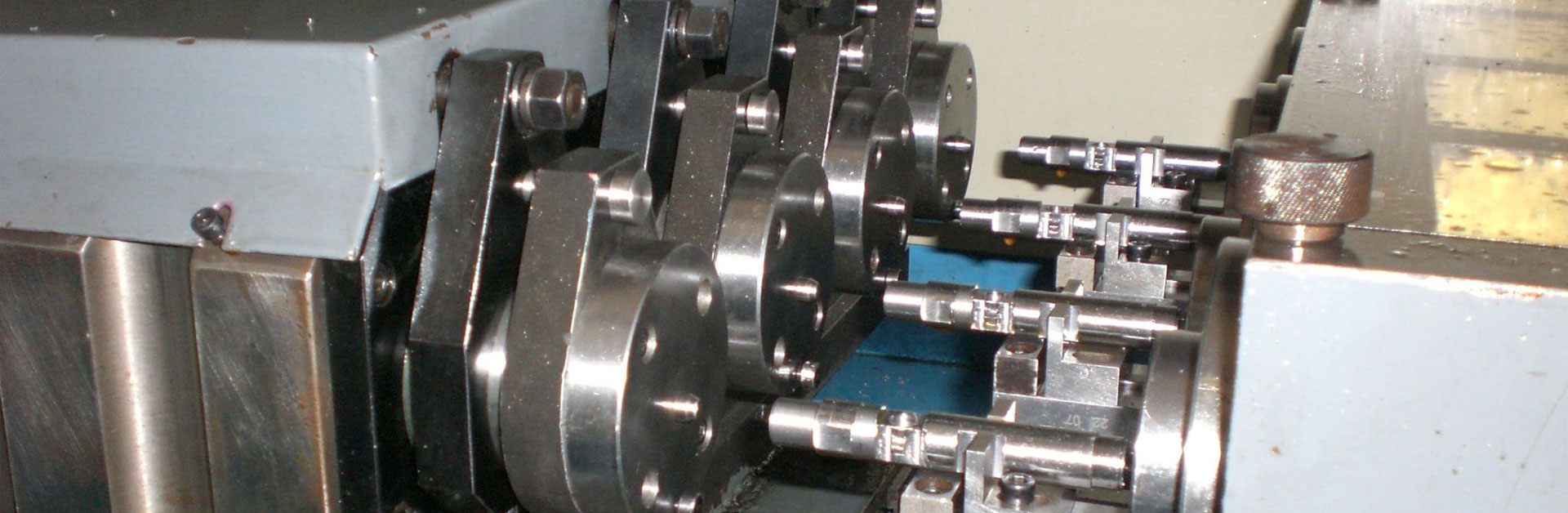

In the cutting process, chipping chips will splash and hurt people, and it is easy to damage the Swiss bed; while long strips of chips will be wrapped around the workpiece or tool, easily scratching the workpiece, causing tool damage, and even affecting worker safety. For automatic machining machines such as CNC Swiss, due to the large number of tools and the close relationship between the tool holder and the tool, the problem of chip breaking becomes even more important. As long as the chip breaking of the tool is not reliable, the automatic cycle of the Swiss bed may be destroyed. Even destroying the normal operation of the entire automatic line, so when designing, selecting or sharpening tools, the reliability of tool chip breaking must be considered. And for Swiss beds, etc., and should meet the following requirementsAnalysis of chip breaking of Swiss machining parts by China precision machining factory

- Swarf must not be tangled around the tool, workpiece and adjacent tools and equipment;

- The chips should not be splashed to ensure the safety of the operator and the observer;

- During finishing, the chips should not scratch the processed surface of the workpiece, affecting the quality of the processed surface;

- Guarantee the durability of the tool, do not wear it prematurely and try to prevent its damage;

- When the chips flow out, it does not hinder the injection of cutting fluid;

- The chips will not scratch the machine tool guide rail or other parts.

Swiss lathe daily management and matters needing attention

1. Precautions when installing Swiss lathe, pay great attention to avoid installation deviations during installation.

- The tightening of the gland should be performed after the coupling is aligned, the bolts should be evenly supported, to prevent the end of the gland from deflecting, check each point with a feeler gauge, the error is not greater than 0.05 mm;

- Check the fit clearance (that is, concentricity) of the gland and the outer diameter of the shaft or bushing. The circumference should be uniform. Use a feeler gauge to check that the tolerance of each point is not greater than 0.01 mm.

2. The spring compression should be carried out according to the regulations.

The Tianjin lathe is not allowed to be too large or too small, and the error is required to be 2.00 mm. Excessive assembly increases the specific pressure of the end face, and the end face wears at another speed. Too small will cause insufficient specific pressure and cannot play a sealing role.3. After the moving ring is installed, the beard must be able to move flexibly on the shaft.

After the Jinshang lathe presses the moving ring against the spring, it should automatically spring back.12 small experiences in CNC machining

At present, many domestic CNC machine tool operators are classified as follows: some operators are very familiar with mechanical processing, ...

Read More →

Selection of parting surface of die casting mold

In order to remove the blank from the die casting mold, the mold needs to be properly divided into several ...

Read More →

What is sheet metal?

Sheet metal is a metal product processing technology, and there is no complete definition of sheet metal so far.According to ...

Read More →

Where is the road to CNC machining development?

A few days ago, PTJ Engineering issued a document saying that it “processed CNC low-cost orders.” This will hurt yourself ...

Read More →

Skillful use of 4 types of CNC Machining technology

First, the undercut knife method Outer convex processingAs shown in FIG. 1, when the outer opening is projected outward, the ...

Read More →

Stainless steel UG crankshaft CNC machining technology

The crankshaft is the center of the internal combustion engine and the core of the engine. If the function cannot ...

Read More →

Table of Contents

Our service

- Cnc Machining

- Swiss Turning

- Swiss Machining

- 5 Axis Machining

- Precision Turning

- Swiss Screw Machining

- Turn-Mill Machining